Traditional extruder motor:When it is driven by variable frequency controller, only open-loop control and speed control can be realized. The speed is unstable because there are slips between the actual speed and the rotor speed. At the same time, the overload capacity is weak. When the motor reaches the rated speed, the force it produces could not meet the requirement of the actual extrusion, thus would cause the alarm and shutdown,making the motor unefficient. What's more, the quality of the extruded product is bad. In addition, It has other disadvantages such as low accuracy (in position, movement, force distance and location), large volume which need large installation space and wasting cost.

Servo extruder motor : Closed-loop control can be carried out, which can control not only speed, but also position and movement, force distance and positioning, so as to achieve accuracy and stability, and will not cause death and alarm due to low overload capacity. At the same time, there is no slip between rotor speed and actual speed, and the extruded products are more uniform and smooth. Due to the distinctions of structural design and manufacturing materials, the product is smaller in size with a compact structure and convenient for installation.

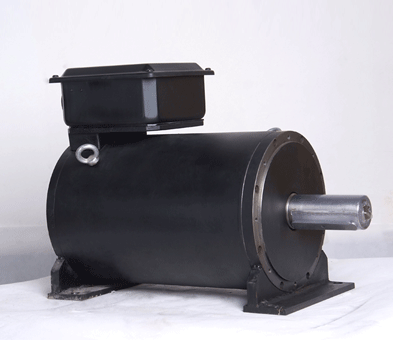

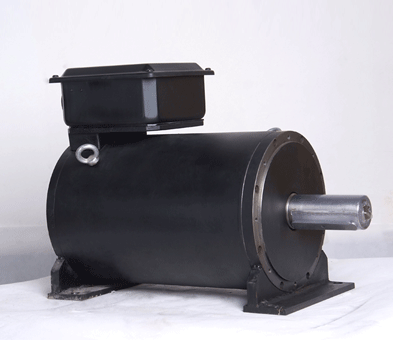

SE-GZ6 Series Water-cooled Permanent Magnet Servo Motor, can be matched with domestic and foreign actuators to form a direct drive servo system with low speed, high torque and strong overload performance, which can compensate the clearance of gearbox gears and make the extrusion effect more smoothly.